Sprayer tank for bitumen, modified bitumen and emulsion, machine with spray bar and pump completely heated and insulated

- 36 hp liquid-cooled diesel engine with independent electric start, operating all parts of the machine.

- Height of the spray bar nozzles 500 mm from the ground.

- Bitumen spraying through cut nozzles.

- Hand gun (for emulsion only) when working in an uncomfortable position.

- Gas oil burner supplied at 12V for heating bitumen.

- Abt. 80,000 kcal diathermic oil boiler with burner operating at 12 or 24 volts.

- Control board in the truck driver’s cab (bar moved up and down, bar enlarged, spraying start and stop, emergency stop, leds for every single nozzle set at work).

- Rear electric board with 2 pcs. digital displays for bitumen / diathermic oil temperature control (Controls for handling the spray bar, burner power on/off, diathermic oil pump on/off, spraying start and stop, emergency stop, control pilot lamps)

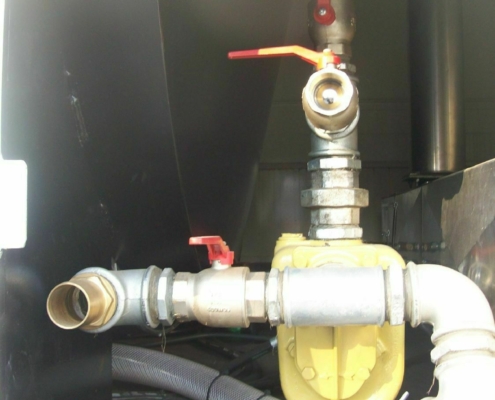

- Bitumen recycling device if sediments build up at the bottom of the tank.

- Compressed air device cleaning the circuit at the end of work.

- Gas oil washing device with independent tank.

- Quick side discharge of the bitumen tank.

- Lifting hooks.

- Aluminium ladder and walkway with folding handrail.

Description

The spray tank for bitumen, modified bitumen and emulsion of the Bruno Group CTB line is a top-range machine, used for large-scale works, such as building roads and motorways (even with draining asphalt) since its construction technology can spray any kind of bitumen and emulsion (even special modified bitumen) without any problem.

The tank is completely heated, insulated in all its parts and aluminium-coated; the spraying plant can evenly meter bitumen at high temperatures before laying asphalt on the rod bed.

The capacity of the spray tank for bitumen, modified bitumen and emulsion is ranging from 5000 lt to 12000 lt.

The machine is designed for direct assembly on the truck supplied by the customer and it has a control board in the cab enabling the operator to know exactly how many nozzles are working (thanks to indicator leds); it is also possible to incorporate a computer controlling the quantity of bitumen laid down per square metre with the utmost care.

Bitumen is hot-loaded into the tank at the bituminous conglomerate plant through a flexible pipe in the upper hatch and kept at the temperature set-point thanks to a diathermic oil heating coupled with a second plant complete with a 12V DC gas oil burner (if the machine is used to spray the bituminous emulsion at a low temperature).

The bitumen temperature is raised to a value ranging from 160°C to 200°C and the internal temperature is kept constant during transport and work cycles.

Temperature is regulated through a simple and user-friendly digital display.

Spraying occurs through a special bitumen pump submerged into the tank, whose flow rate can reach 500 litres per minute; the pump is connected with a hydraulic motor enabling the operator to work even at extremely low temperatures and with any kind of bitumen.

The standard spray bar is equipped with 20 pcs. cut nozzles, each one operated by a compressed air cylinder; heated by diathermic oil, it is complete with an automatic handling system operated by hydraulic cylinders enabling the operator to move the bar up and down and to enlarge it.

At the end of work, it will be necessary first to clean the machine by using compressed air drawn from the truck (air purges the bitumen conduits) and then to operate the gas oil washing device (supplied with a tank as a standard) for a complete clean cycle.

Technical data and available models

| MODEL | CAPACITY lt | TRUCK BODY LENGTH mm | MAX. LENGTH mm | MAX. WIDTH mm | HEIGHT mm | TANK DIAMETER mm | SPRAY BAR WIDTH mm | GAS OIL HEATING |

| Spraytank CTB 5000 | 5000 | 4650 | 5500 | 2400 | 2200 | 1800 | 2800 – 4500 | AT 12 VOLTS |

| Spraytank CTB 6000 | 6000 | 5150 | 5950 | 2400 | 2300 | 1800 | 2800 – 4500 | AT 12 VOLTS |

| Spraytank CTB 7000 | 7000 | 5450 | 6350 | 2400 | 2400 | 1800 | 2800 – 4500 | AT 12 VOLTS |

| Spraytank CTB 8000 | 8000 | 5900 | 6700 | 2400 | 2400 | 1800 | 2800 – 4500 | AT 12 VOLTS |

| Spraytank CTB 10000 | 10,000 | 5900 | 6700 | 2400 | 2400 | 2000 | 2800 – 4500 | AT 12 VOLTS |

| Spraytank CTB 12000 | 12,000 | 6000 | 6800 | 2400 | 2500 | 2100 | 2800 – 4500 | AT 12 VOLTS |

Optional

Fields of application

Video

Video not available for this machine.