Sprayer for bituminous emulsion US

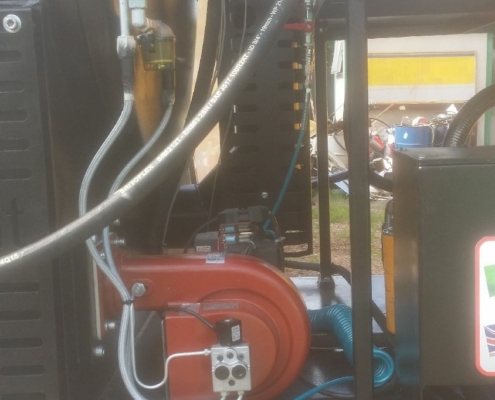

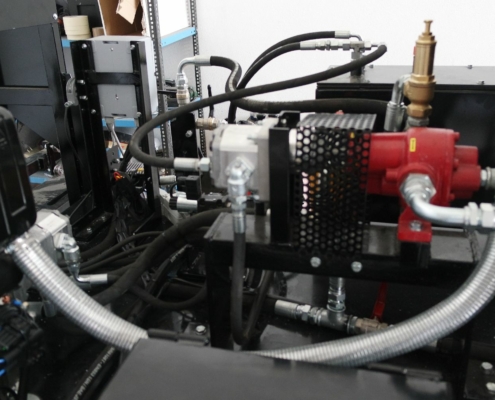

- 10 hp diesel engine with independent electric start, operating all parts of the machine.

- Height of the spray bar nozzles 500 mm from the ground.

- Emulsion spraying through cut nozzles.

- Hand gun when working in an uncomfortable position.

- Gas oil burner supplied at 12V for heating the emulsion.

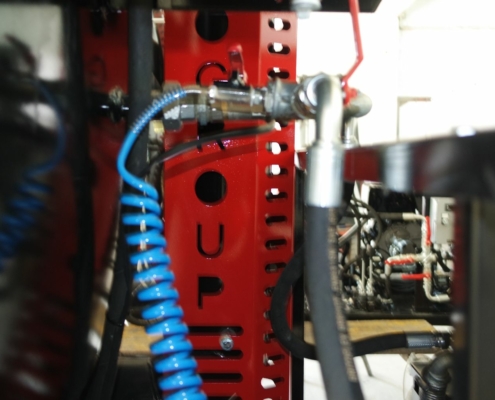

- Pushbutton panel with switch in the truck driver’s cab (to enable drivers to start and stop spraying the emulsion).

- Side electric board with digital display for temperature control, power on-off switch, emergency stop and lamps for failure signal.

- Emulsion recycling device if sediments build up at the bottom of the tank.

- Device pouring the emulsion from the drums into the tank by means of a spray pump.

- Compressed air device cleaning the circuit at the end of work without using gas oil.

- Gas oil washing device.

- Quick side discharge of the emulsion tank.

- Lifting hooks.

Description

The sprayer for bituminous emulsion of the Bruno Group US line is one of the machines best appreciated on the domestic and international market since it has an excellent price – performance ratio and, even if it is a simple and low-cost machine, it has all that is necessary to enable the operator to distribute the emulsion uniformly on the road bed before laying asphalt.

The US line tank sprayer are designed to be mounted even on small-size trucks having a low load capacity.

The capacity of US tank sprayers for bituminous emulsion is ranging from 1000 lt to 5000 lt.

The emulsion is loaded into the tank at the bituminous conglomerate plant through a flexible pipe in the upper hatch and kept hot (at a temperature ranging from 40°C to 60°C) thanks to a burner operating at 120V DC; heating is adjustable through a digital display and the inner temperature is kept constant.

The emulsion is conveyed to the site and sprayed onto the asphalt through the spray bar by using an additional manual gun that can reach the most difficult points of the road surface.

Spraying occurs through a special emulsion pump with a heat storage tank (heated by the engine exhaust gas) connected with a hydraulic engine operated by a lever distributor, which enables the operator to work even at extremely low temperatures and with any kind of emulsion.

A vertically mobile bar operated by 2 hydraulic cylinders driven by a lever distributor will be moved up and down; a standard bar will open manually, but it is possible to install a bar opening automatically when driven by two hydraulic cylinders.

At the end of work, it will be necessary first to clean the machine by using compressed air drawn from the truck (air purges the emulsion conduits) and then to operate the gas oil washing device for a complete clean cycle.

Technical data and available models

| MODEL | CAPACITY lt | TRUCK BODY BASE LENGTH mm | MAX. LENGTH mm | MAX. WIDTH mm | HEIGHT mm | TANK DIAMETER mm | SPRAY BAR WIDTH mm | GAS OIL HEATING |

| US 1000 short | 1000 | 3125 | 3900 | 1150 | 2100 | 1260 | 1800 – 3500 | AT 12 VOLTS |

| US 1000 std | 1000 | 3425 | 4200 | 1150 | 2100 | 1100 | 1800 – 3500 | AT 12 VOLTS |

| US 2000 | 2000 | 3900 | 4600 | 1150 | 2400 | 1260 | 2800 – 4500 | AT 12 VOLTS |

| US 3000 | 3000 | 4670 | 5300 | 1150 | 2400 | 1260 | 2800 – 4500 | AT 12 VOLTS |

| US 4000 | 4000 | 5170 | 5800 | 1700 | 2400 | 1600 | 2800 – 4500 | AT 12 VOLTS |

| US 5000 | 5000 | 5670 | 6300 | 1700 | 2400 | 1600 | 2800 – 4500 | AT 12 VOLTS |